ITEM SPECIFICS

-

Brand

Model .Unbranded

-

origin

Republic of Korea

-

Size(Capacity)

PRODUCT DESCRIPTION

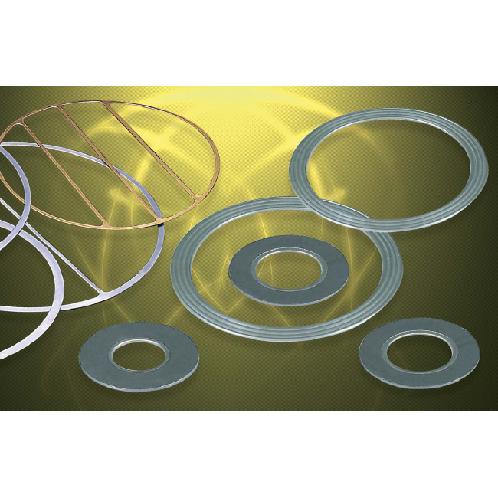

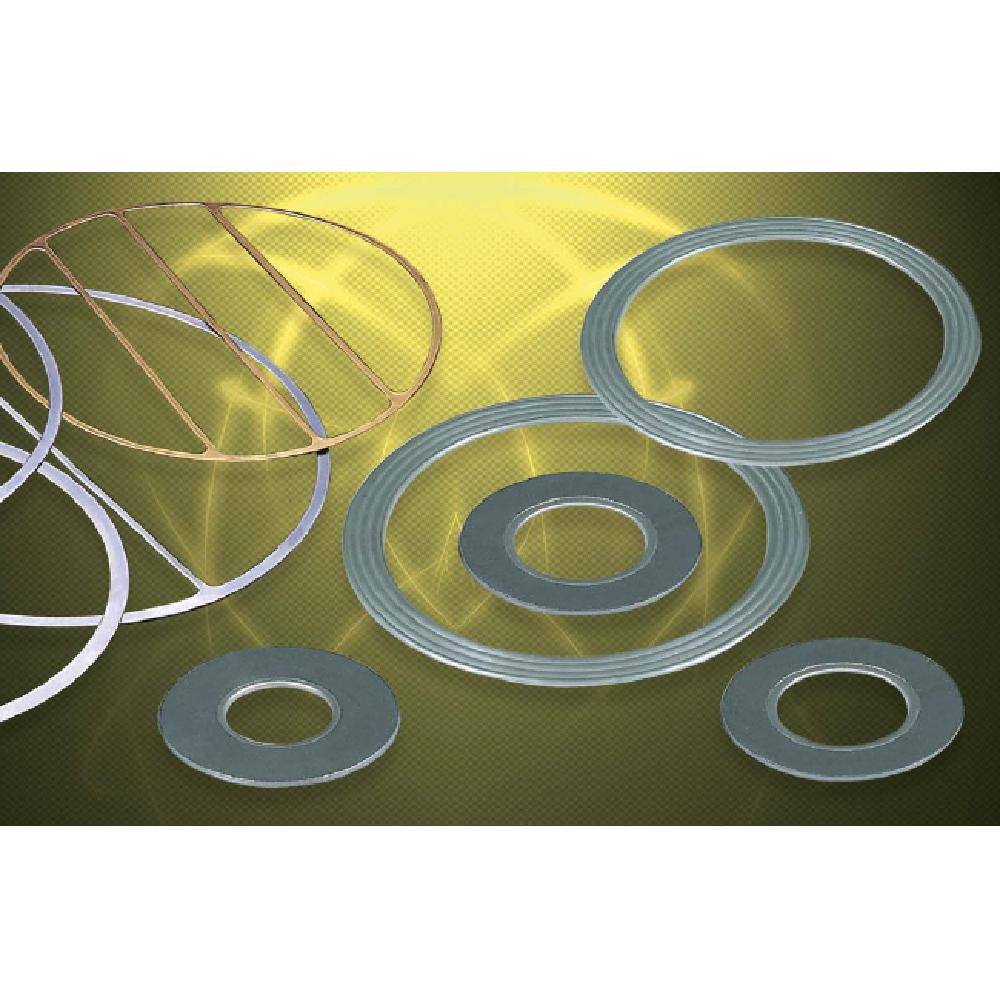

Korea Fuji metal-jacketed gaskets are fabricated with Non-Metallic for inner filler as metallic of outer shell.

They are widely used in heat exchangers, Boilers, Pumps, valves with high temperature and

severe corrosion conditions for various plants. (Powers, Chemicals, Oil Refineries, Iron plants)

Metal-jacketed gaskets fabricated by hand in various shapes and sizes as Round, Oval,

and Oblong in order to supply. Besides, many materials used according to temperature,

pressure, and corrosive conditions. (Please refer to page 78/80 for jacket and filler material)

Recently for sealing improvement Graphite and PTFE tape glued together on both sides of gasket in view of increasing consumption.

Effective is especially high in case of damage caused by corrosion on flange surface.

Single Jacketed Gaskets

Gaskets are jacketed with one thin metal to inner filler.

his sort of gasket is used in Boiler, compressor, Pump, Diesel and Gasoline Engines of low

pressure, however not recommended for standard pipe flange, minimum flange width 6.4mm,

nominal gasket thickness 3.2mm Also available are round jacketed gaskets applicable to Boiler

Man-hone, Steam trap and Sight Glass.

Double Jacketed Gaskets

The filler material is completely enclosed by a two piece metal jacket, which covers both the inside and outside diameters and both contact surfaces KFP 471 is similar to style KFP 470 with the exception that the metal jacket is formed from a corrugated jacket providing better resilience than the KFP 470, since the corrugations form multi-seals across the flange sealing face.

Double Shell Type Jacketed Gaskets

KFP 474 is a double shell type jacketed gasket constructed of two reversed wrap-round shells. This provides superior flange support and handle ability and provides better resistance to high pressures.

Double-jacketed gaskets are used on Boiler and Heat Exchanger applications when ample bolting

is available to correctly seat the gasket. They are designed for high pressure and temperature

applications up to and inclusive of class 900. The temperature limitation of the gasket is dictated

by the combination of metallic and non-metallic materials used in its construction.

Flange widths as narrow as 8mm(5/16 ) could be manufactured, dependent on diameter. Very large

gasket diameters could also be produced. Nominal gasket thickness 3.2mm(1/8 ).

Gaskets could be manufactured with either integral or welded pass partition bars, in a variety of

complex configurations. Some of the most common pass bar configurations are shown on page

34.

Solid Corrugated Metal Gaskets

As the name suggests, the solid corrugated metal gasket is comprised solely of metal and does

not contain any non-metallic fillers in its construction. The temperature limitation of the gasket is

therefore only effected by the metal selected.

The corrugations provide multi-seals across the face of the gasket and inherent resilience.

A minimum of three corrugations is recommended and gasket thickness is approximately 50% of

the corrugation pitch.

Typically used for high temperature applications and applications involving steam, water, gas, oil

etc. up to

Features

- Good sealing performance

- The long life expectancy

Spec

According to the ANSI, ASME, API, DIN, BS, JPI, JIS, KS etc.

PAYMENTS DETAILS

- Telegraphic Transfer : T/T

- Name : JONG-TAI LEE

SHIPPING

- #517, Life Arcade, 614-33, Guro-dong, Guro-gu, Seoul 152-050, Korea, 서울특별시,

The person in charge

Address

#517, Life Arcade, 614-33, Guro-dong, Guro-gu, Seoul 152-050, Korea, 서울특별시,

-

- Business Type :

- Manufacturer

-

- Main Product :

-

- Established :

- 1985-01-01

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Please enter the text on the left image to prevent automatic input.

0 / 4000

CUSTOMER REVIEWS (0)

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

GOLD

GOLD

- KOREA FUJI PACKING Co., Ltd. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★