ITEM SPECIFICS

-

Brand

Model Turbine Compressor DiaphragmFLOWDY

-

origin

Republic of Korea

-

Size(Capacity)

CUSTOMIZED

-

Dimensions

Customized

-

Weight

Customized

-

age-appropriate

All ages

PRODUCT DESCRIPTION

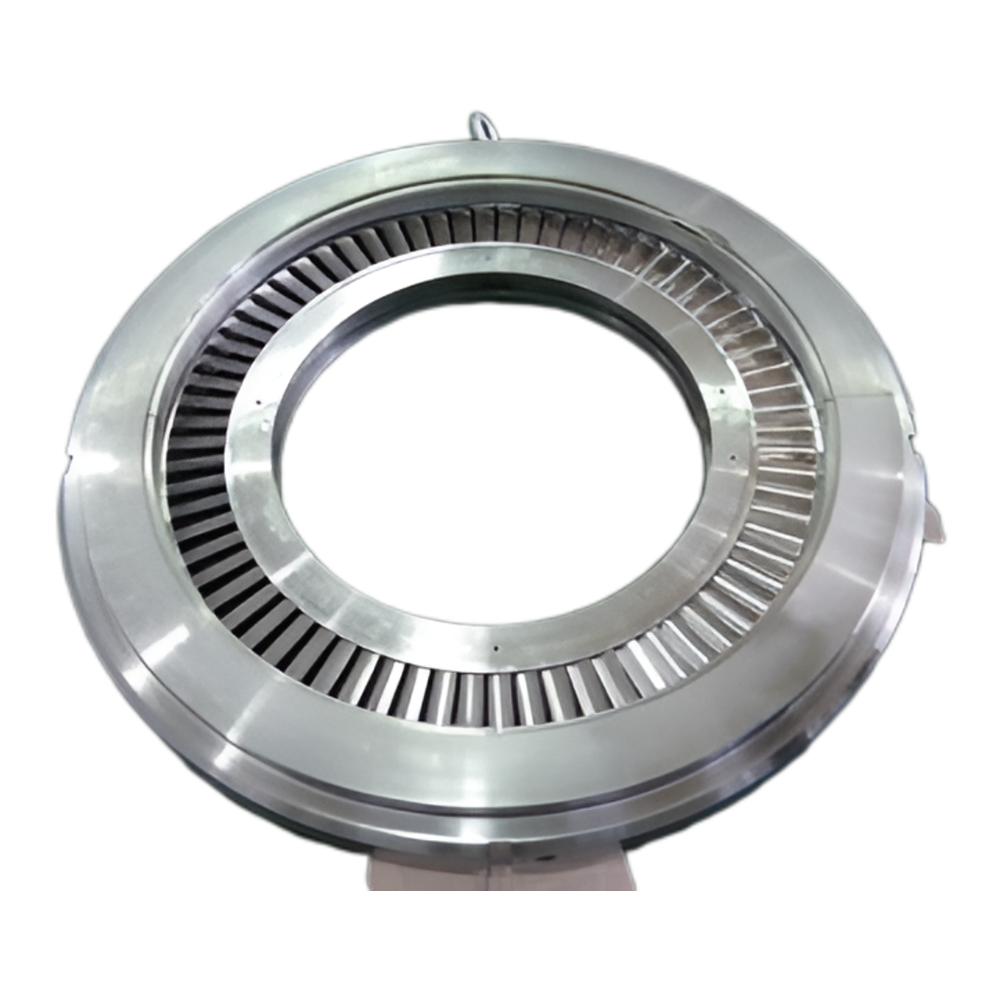

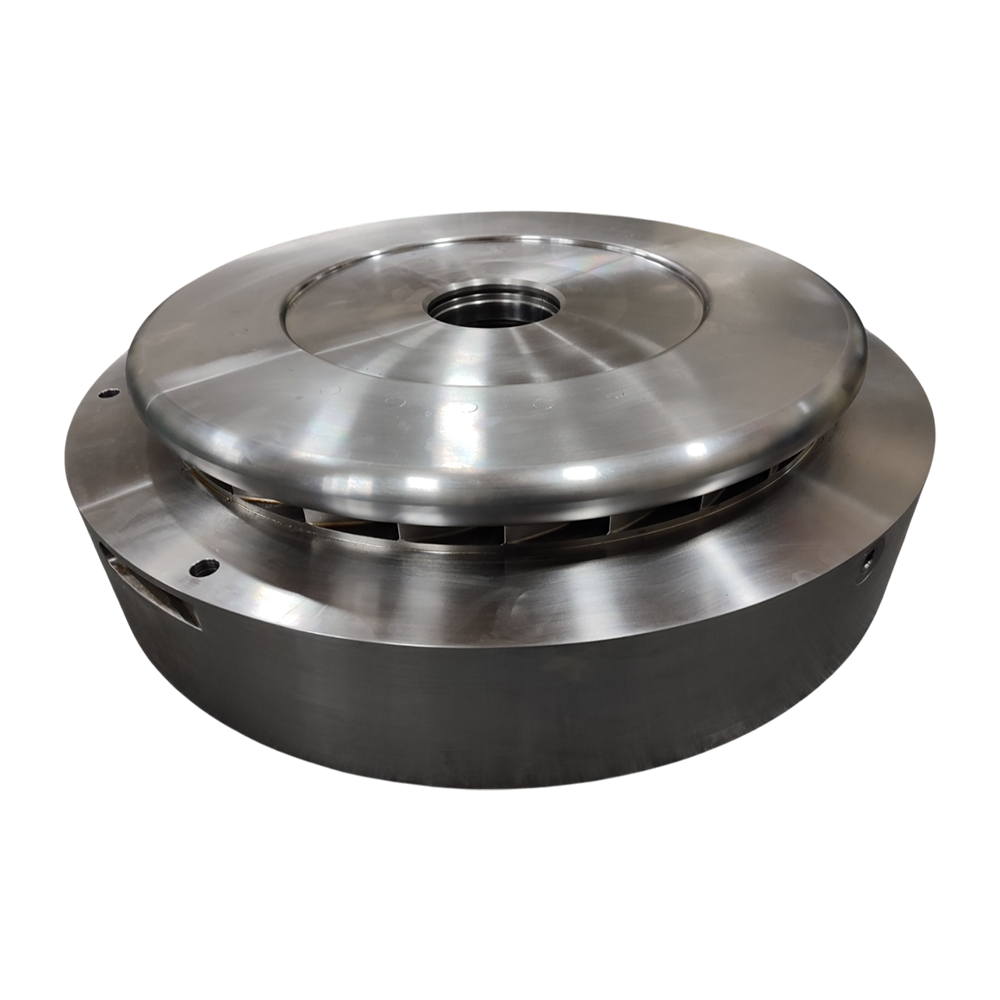

Turbine Compressor Diaphragm

The compressor diaphragm is a vital component in multi-stage axial compressors, commonly used in gas and steam turbines. Positioned between rotating blades, it houses stationary vanes (stators) that guide high-velocity airflow to the next stage at the optimal angle, ensuring aerodynamic efficiency and consistent pressure throughout the compression process. In addition to directing flow, the diaphragm provides structural support, seals between stages, and may incorporate features such as cooling passages or labyrinth seals to withstand high temperatures and minimize leakage.

To endure harsh operating conditions, materials such as nickel-based alloys, stainless steels, and titanium are commonly used for their excellent heat and corrosion resistance. Our diaphragms are manufactured through precision machining, with tight-tolerance control and strict quality assurance, meeting the high standards required in power generation, marine propulsion, oil & gas, and other industrial turbomachinery applications.

Deployed in turbines operating in power plants, petrochemical facilities, and offshore environments, our compressor diaphragms are built for performance and durability. From drawing to production, we offer complete manufacturing support—including material selection, non-destructive testing (NDT), heat treatment, and surface finishing—to ensure long-term reliability and optimal performance in even the most demanding environments.

To endure harsh operating conditions, materials such as nickel-based alloys, stainless steels, and titanium are commonly used for their excellent heat and corrosion resistance. Our diaphragms are manufactured through precision machining, with tight-tolerance control and strict quality assurance, meeting the high standards required in power generation, marine propulsion, oil & gas, and other industrial turbomachinery applications.

Deployed in turbines operating in power plants, petrochemical facilities, and offshore environments, our compressor diaphragms are built for performance and durability. From drawing to production, we offer complete manufacturing support—including material selection, non-destructive testing (NDT), heat treatment, and surface finishing—to ensure long-term reliability and optimal performance in even the most demanding environments.

Company Overview

FLOWDY is a manufacturing company specializing in rotating turbine parts of Steam Turbine and Gas Turbine and high speed produces products by carrying out all processes such as processing special alloy materials directly through centrifugal casting, forging, and heat treatment. It consists of the core parts of steam and gas turbines in nuclear, hydro, thermal and combined thermal power plants. manufacturing company specializing in rotating turbine parts of Steam Turbine and Gas Turbine and high speed produces products by carrying out all processes such as processing special alloy materials directly through centrifugal casting, forging, and heat treatment.

Other Products

R&D CERTIFICATE

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Telegraphic Transfer : T/T

- Name : JOON SEOB KIM

SHIPPING

Shipping from :

Republic of Korea

- 54 Charyong-ro 48beon-gil Uichang-gu, Changwon-si, Gyeongsangnam-do (51391)

Flowdy

The person in charge

John KIMAddress

54 Charyong-ro 48beon-gil Uichang-gu, Changwon-si, Gyeongsangnam-do (51391)

Introduction

FLOWDY is a manufacturing company specializing in rotating turbine parts of Steam Turbine and Gas Turbine and high speed produces products by carrying out all processes such as processing special alloy materials directly through centrifugal casting, forging, and heat treatment. It consists of the core parts of steam and gas turbines in nuclear, hydro, thermal and combined thermal power plants. manufacturing company specializing in rotating turbine parts of Steam Turbine and Gas Turbine and high speed produces products by carrying out all processes such as processing special alloy materials directly through centrifugal casting, forging, and heat treatment.

-

- Business Type :

- Manufacturer

-

- Main Product :

- Compressor Diaphragm, Packingring

-

- Established :

- 2016-09-01

-

- Total Annual Revenue :

- 2~3 billion (KRW)

-

- Total Employees :

- 5~10 people

R&D CERTIFICATE

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- 2~3 billion (KRW)

-

- Total export revenue (previous year in USD)

- 2,000

-

- Number of foreign trade employees

- 5~10 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

- MEMBER

- Flowdy Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★